What Causes Fisheyes or Craters in Powder Coating?

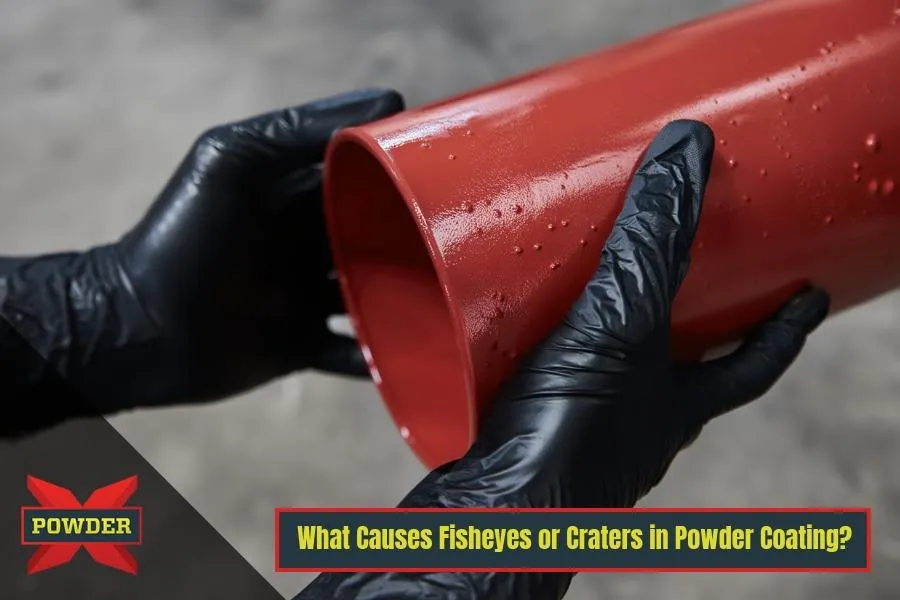

You’ve just pulled a part from the oven, and instead of a smooth, glassy finish, you see tiny craters or round “fisheye” spots scattered across the surface. It’s one of the most frustrating defects in powder coating and one of the most avoidable.

The good news? Every fisheye has a cause, and once you identify it, you can prevent it from ever happening again.

What Are Fisheyes in Powder Coating?

Fisheyes are small, circular voids or craters in the coating where powder has pulled away from the surface during curing. They’re usually surrounded by a smooth ring, making them look like tiny eyes staring back at you.

The Usual Suspects: Causes of Fisheyes & Craters

1. Contamination on the Part Surface

The #1 cause of fisheyes is surface contamination that repels powder during curing.

Oils & Grease – From handling, machining, or even fingerprints.

Silicone – From lubricants, sealants, or nearby processes.

Dust/Dirt – Especially from grinding or sanding without proper cleaning.

Prevention:

Always follow a consistent pretreatment process.

Wear gloves when handling prepped parts.

Keep coating and prep areas free of airborne contaminants.

2. Dirty or Moisture-Contaminated Air Supply

If your compressed air carries oil or water droplets into your spray gun, they’ll land on the part and create adhesion issues.

Fix:

Install and maintain air dryers and oil coalescing filters.

Drain tanks daily.

Change filters on schedule.

3. Cross-Contamination in the Booth

Overspray from another color, texture, or powder type can land on the part and cause craters.

Prevention:

Clean the booth thoroughly between color changes.

Use dedicated guns and hoppers for sensitive powders.

4. Outgassing from the Substrate

Some metals, especially castings, contain trapped air, moisture, or contaminants that escape during curing, pushing the coating away.

Fix:

Prebake parts to drive out trapped gasses before coating.

Use outgassing-forgiving powders when working with porous metals.

5. Poor Powder Storage

Powder stored in high humidity or fluctuating temperatures can clump and spray inconsistently, leading to thin spots and voids.

Solution:

Store powder in a cool, dry place.

Keep boxes sealed when not in use.

How to Diagnose the Source

When fisheyes appear, don’t just recoat and hope for the best, that’s a short-term fix that hides the root problem.

Check your pretreatment process first.

Inspect air supply filters and dryers.

Look for silicone, oil, or other contaminants near your coating area.

The Bottom Line

Fisheyes and craters are like warning lights on a dashboard, they’re telling you something’s wrong with your process. Fix the root cause and you’ll not only eliminate the defect but also improve overall coating quality and customer satisfaction.