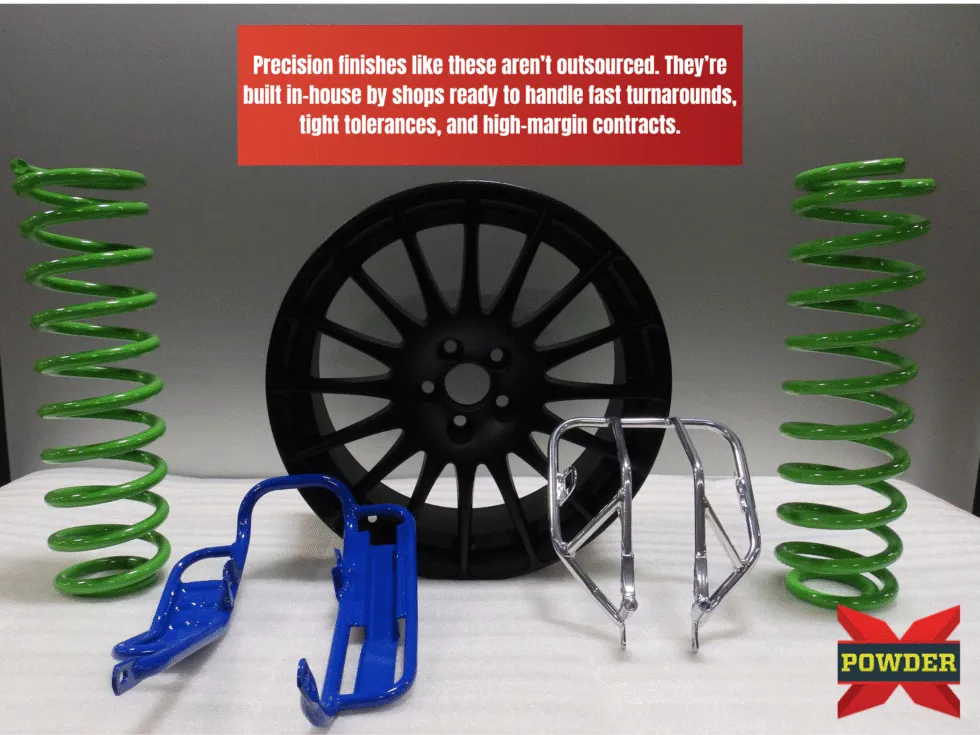

Why In-House Powder Coating Is the Key to Higher Margins and Government Contracts

Let’s be honest: outsourcing might have worked when you were doing basic parts on a flexible timeline. But today?

In-house powder coating for government contracts is a method that prioritizes speed, precision, and traceability to win contracts.

And that’s exactly what in-house powder coating delivers, especially for government contract requirements.

If you’re serious about growing beyond commodity work and stepping into higher-margin jobs or government contracts, bringing the coating process in-house isn’t just an upgrade… It’s a strategic move, especially with in-house powder coating.

The Problem with Outsourcing: You’re at the Mercy of Their Timeline

When you send your parts out to coaters:

– You lose control over lead time

– You can’t verify how tightly they manage film build

– You can’t track their process for ISO, Mil-spec, or OEM audits

– You’re one phone call away from a missed shipment and a canceled contract

With outsourcing, especially for government contracts, risk exposure increases dramatically.

In-House Coating = Total Control Over Critical Variables

When you control the coating process, you control:

Lead time – Eliminate transport and waiting periods

Film thickness – Tune your guns and line to dial in specs within microns

Documentation – Log every stage, rinse, and cure cycle for compliance

Rework – Fix issues immediately without a 3-day delay

Cost structure – Know your margins down to the penny

“You can’t bid on precision work if your finishing process is unpredictable. In-house coating brings it under your roof and under control.” – Joey Golliver, ensuring government contracts are handled efficiently.

Why It Matters for Government and Defense Contracts

If you want to play in the DoD, aerospace, or government procurement arena, you need:

Compliance with Mil-Spec coatings (MIL-PRF, MIL-DTL)

Traceability of every part and process step

Proof of tight process controls and fast correction cycles

ITAR or ISO 9001 workflows that you can’t fake with a 3rd party coater

In-house powder coating helps firms prove that their processes meet government contract standards.

With in-house coating, you own the process and the paper trail crucial for government contracts.

Fast Turnaround = Competitive Advantage

In commercial markets, fast turnaround closes deals and aligns with government contract expectations.

Your competitors are quoting 3-week lead times. You quote 7 days.

Why? Because you’re not waiting for a subcontractor to fit you into their schedule.

You coat the parts the moment they’re ready.

You ship on time.

And your customer? They come back.

“Speed and quality are what win repeat work. In-house powder coating gives you both.”

Higher-Margin Work Loves Consistency

The more demanding the customer, the more they value:

– Precise specs

– Predictable timelines

– One point of accountability

Those are the buyers who pay higher prices for consistency, because they can’t afford failure.

Bringing powder coating in-house signals to those buyers:

“We own our quality. We’re built for your standard.” In-house operations meet the specific needs defined by government contracts.

The Bottom Line

In-house powder coating isn’t just a finishing process. It’s a growth lever, especially vital for government contracts.

It reduces lead times

It increases control

It opens doors to government, aerospace, and high-spec commercial work

It improves margins and customer retention

Want to step out of the low-bid commodity race and into high-value, contract-driven work?

Bring your coating in-house and build your edge from the inside out.