The 8 Essential Tools You Need for Powder Coating Quality Control

If you’re not testing, you’re guessing. That’s why powder coating quality control tools are essential for ensuring reliable results.

That’s not just a catchy line, it’s the hard truth in the powder coating business. Whether you’re just getting started or looking to tighten up your operations, quality control testing isn’t optional. It’s what separates the amateurs from the pros, the one-time coaters from the shops with booked schedules and 5-star reputations.

Here’s the deal: every part that leaves your shop is a business card. If it fails in the field, peels, chips, or fades, it doesn’t matter how nice your finish looked on Day 1. The customer sees failure.

And worse? So do their friends.

Why Quality Control Is Your Best Sales Tool

You already know quality matters. But verifiable quality, tested quality, is your silent salesperson. When can you show a potential customer your QC process? You just became more than another shop with a spray gun. You became the expert.

And that kind of trust?

It’s what builds long-term, high-ticket relationships.

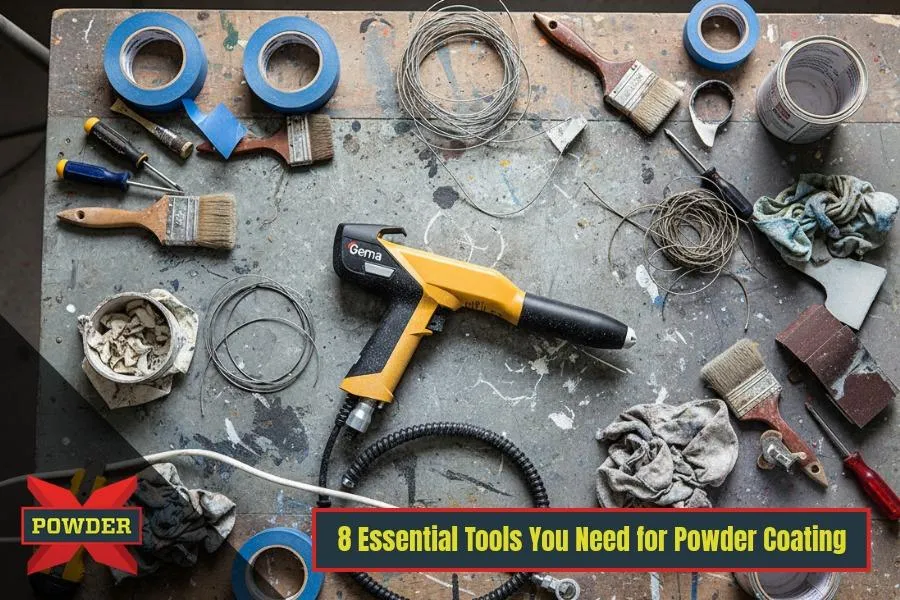

The 8 Must-Have Quality Control Tools for Powder Coating

Let’s break it down. These are the core tools you need for effective, professional-quality control testing. If you’re missing any of these, your coating system might be running blind.

1. Ground Resistance Tester

What it does: Verifies that your parts have an adequate ground (usually below 1 megaohm) to accept powder.

Why it matters: If the powder won’t stick, it’s probably not the powder, it’s the ground. Poor grounding is one of the most common (and preventable) causes of inconsistent coverage, orange peel, and thin spots.

Joey Note: “No ground? No stick. I don’t care how fancy your gun is, without a good ground, it’s like trying to throw darts in zero gravity.”

2. Digital Coating Thickness Gauge

What it does: Measures cured film thickness in mils or microns.

Why it matters: Applying too much powder can lead to outgassing and orange peel. Too little and your coating won’t meet durability specs. You need to hit the goldilocks zone, just right.

Look for a gauge that can read both ferrous and non-ferrous substrates.

3. Cure Test Kit (Solvent Rub Test)

What it does: Confirms full cure by applying MEK or xylene to the finished part and observing resistance.

Why it matters: An under-cured part might look great today, but it’ll chip, fade, or fail tomorrow. A solvent rub test exposes cure problems before your customer does.

4. Infrared Thermometer or Thermocouple Probe

What it does: Measures part temperature at the part, not just oven air temp.

Why it matters: Powder doesn’t cure at air temperature, it cures when the part reaches the correct temperature for the correct time. You need to verify metal temp, not guess from a wall dial.

5. Adhesion Test Kit (Cross Hatch or X-Cut Test)

What it does: Tests how well the powder coating adheres to the substrate.

Why it matters: Poor adhesion could mean surface contamination, improper cure, or bad pretreatment. If your coating peels off with tape, your customer will too.

6. Gloss Meter

What it does: Measures the gloss level of the cured coating.

Why it matters: Different gloss levels = different perceived quality. Especially in commercial or architectural jobs, you’ll need to prove your gloss hits the spec.

7. Salt Spray or Corrosion Test Panels

What it does: Exposes your pretreatment and powder system to accelerate corrosion conditions.

Why it matters: This is how you prove long-term performance. It’s not something you do every day, but periodically testing your process on panels ensures your system is dialed in.

8. Compressed Air Quality Check

What it does: Monitors moisture and oil in your air lines.

Why it matters: Moisture in your powder line = mud. Joey says it best:

“Powder is hygroscopic, so it absorbs moisture. Powder plus moisture equals mud. And mud doesn’t bake out very well. Don’t overlook the importance of good air.”

Clean, dry air is the foundation of a consistent finish.

Don’t Just Buy Tools, Use Them

Having these tools in your shop is only half the battle. Using them regularly and recording your results is where the magic happens. That’s when you start seeing patterns. That is when you get ahead of problems. That’s when your shop becomes the go-to name in town.

And if you’re looking to stand out in a competitive market, quality control is your edge.

Your Next Step: Make QC a Routine, Not a Rescue

Here’s the truth most coaters won’t admit:

Shops that skip QC end up fixing more parts, arguing with more customers, and bleeding more profit than they ever realize.

Invest in these tools. Train your team to use them. Make testing part of your workflow, not a last-minute scramble.

Because the shops who make quality routines?

They’re the ones that grow.