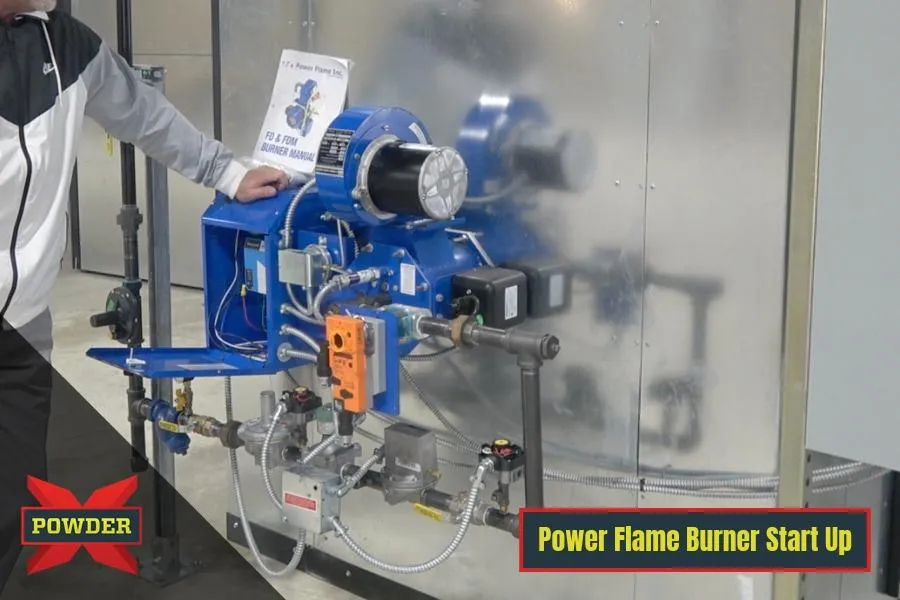

Power Flame Burner Start Up

The video provides a detailed, technical overview of operating and troubleshooting a power flame burner, emphasizing the critical importance of professional handling and proper setup to ensure safety and functionality. The presenter underscores that only a licensed gas technician should start and adjust the burner due to the risks of damage, voiding warranties, or causing hazardous conditions. Key procedural steps include verifying gas pressure within the precise range of 10 to 14 inches water column, using a monometer to avoid false readings, and correctly setting low and high gas pressure alarms with reset buttons. The burner’s ignition process may require multiple attempts to purge air, and the combustion air flow must be adjusted carefully using a slide plate to balance oxygen supply, optimizing fuel efficiency and flame stability. The burner modulates gas flow via voltage signals to the gas pedal, which controls gas input from low to high fire. Proper dial settings and wiring orientation are crucial; incorrect wiring can cause misleading temperature readings, impacting burner performance. The video concludes by emphasizing the importance of following the correct electrical schematics found in the oven’s manual for wiring, not the burner’s troubleshooting diagrams, to ensure proper installation and operation.

Highlights

- Only licensed gas technicians should start or service the power flame burner to avoid damage and safety hazards.

- Gas pressure must be strictly maintained between 10 to 14 inches water column for proper burner operation.

- Use a monometer for accurate gas pressure measurement, avoiding false gauge readings.

- Adjust the combustion air slide plate to find the “sweet spot” for optimal oxygen supply and flame stability.

- The burner gas pedal modulates fuel flow using a 2 to 10-volt signal for efficient temperature control.

- Ensure wiring of temperature sensors is correct; reversed wiring causes false temperature readings and operational issues.

- Always use oven wiring schematics from the manual for installation, not burner troubleshooting diagrams.

Key Insights

- Professional Installation Is Non-Negotiable: The burner’s complexity and potential hazards make it mandatory that only licensed gas technicians handle its startup and adjustments. This protects against costly damage, voided warranties, and severe safety risks, including explosions or fires. The presence of specialized tools such as monometers and gas meters further underscores the need for technical expertise.

- Precise Gas Pressure Control Is Critical: The burner requires gas pressure between 10 and 14 inches water column; deviations below or above this range prevent operation. This strict requirement highlights the sensitivity of the burner to gas supply conditions and the necessity for accurate measurement tools. Using a monometer to double-check gauge readings is recommended because gauges can provide false or inaccurate readings, which can lead to improper burner function or failure to start.

- Gas Pressure Alarms and Reset Mechanisms Provide Safety Oversight: The burner includes low and high-pressure alarms with reset buttons that must be properly configured (low set to ~2 inches, high to ~15-16 inches water column). These alarms prevent unsafe operating conditions by shutting down burner operation if gas pressure is outside safe thresholds. Operators must reset these alarms during startup, as they will trip when gas flow is initially off.

- Airflow Management Is Essential for Ignition and Efficiency: The combustion air slide plate controls airflow from the fan into the burner. Excessive airflow can extinguish the ignition flame, while insufficient airflow reduces combustion efficiency and flame temperature. The recommended procedure is to start with the plate fully closed to light the burner, then gradually open it to find the optimal airflow that sustains ignition and maximizes fuel efficiency. This illustrates the delicate balance between oxygen supply and fuel input critical for effective combustion.

- Modulation of Gas Flow Enables Temperature Control and Efficiency: The burner’s gas pedal receives a variable voltage signal from 2 (off) to 10 volts (full open), controlling gas flow dynamically based on temperature needs. This modulation allows the burner to adjust fuel input in response to operating conditions, improving energy efficiency and temperature stability. The operator must ensure related dials are correctly set (zero position for modulation), as incorrect settings (such as setting the dial to “one”) can disable modulation, causing the burner to run at full capacity continuously, wasting fuel.

- Correct Wiring of Temperature Sensors Is Vital for Reliable Operation: The temperature readings on the control panel rely on properly wired sensors. If these sensors are wired backward, temperature readings will decrease when the burner is heating, causing confusion and potential misadjustments. The video stresses verifying sensor wiring and provides guidance on how to swap wiring connections safely, emphasizing the need to power off equipment before doing so. This point highlights the importance of correct electrical connections for accurate system feedback and control.

- Following Proper Schematics Ensures Correct Installation and Troubleshooting: The presenter advises using the oven’s wiring schematics included in the owner’s manual for all interconnect wiring rather than the burner’s troubleshooting diagrams. This distinction is crucial because burner diagrams are intended solely for troubleshooting, not for initial wiring. Proper documentation ensures consistent, safe, and functional installation practices, preventing wiring errors that can lead to operational failures or safety issues.

The video provides a comprehensive guide that combines technical know-how with safety precautions, ensuring power flame burners operate efficiently and safely when handled by qualified professionals. It emphasizes systematic checks, careful adjustments, and adherence to official documentation to optimize burner performance while minimizing risks.