Why Powder Coating Beats Paint for Texture Variety

When many people think of finishing metal products, they picture smooth, glossy painted surfaces. But powder coating unlocks a whole spectrum of texture possibilities, something that traditional wet paint struggles to match consistently. With powder, you are not just limited to color and gloss you can layer, pattern, and sculpt textures to suit both function and aesthetics.

Texture = Functional & Aesthetic Advantage

Here are a few reasons why textures make powder coating more versatile:

Hides Imperfections

Smooth finishes tend to highlight surface defects, weld lines, sanding scratches, and small dents. A textured powder finish helps mask those irregularities, making parts look cleaner and more uniform. As Tiger Coatings explains, textured finishes "allow the coating to effectively mask small imperfections due to the lack of a smooth surface finish." tiger-coatings.comBetter Grip & Tactile Behavior

For handrails, tool handles, machinery covers, or even decorative panels, texture can add grip or reduce slipperiness. You can choose finishes that are subtly rough, coarse, or tactile without compromising durability.Depth & Visual Interest

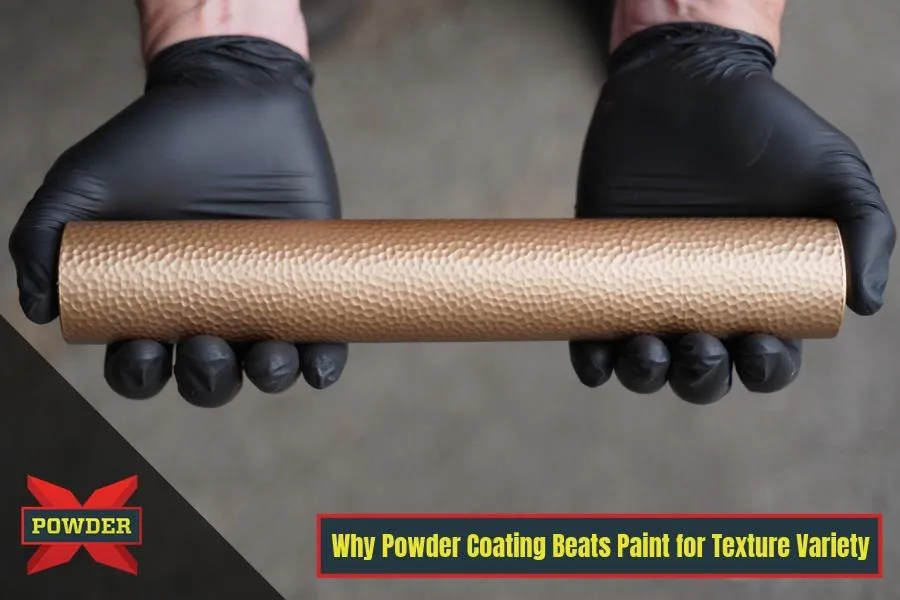

Texture gives shadows and nuance to surfaces. You can go from sand-like grains to hammered metals to wrinkle or vein patterns. These effects provide aesthetic depth a flat paint rarely achieves.Durability Is Still Strong

Textured powders are formulated to meet same or higher wear, chemical, and corrosion resistance as smooth powders. The texture is part of the powder’s performance, not just a superficial add-on.Layering & Effects

Powder coating allows combining textures with color effects (e.g. a matte base plus textured clear, or a coarse texture with metallic highlights). Many suppliers offer “textured clear coats” for that reason.

Because powder is applied as a dry electrostatic process, you're not fighting solvents, sagging, or flow-out which limit the degree of controlled texture in wet paint.

"To outclass paint, you must think three‑dimensionally: texture, layer, depth—powder lets you build that without compromising protection."

— A paraphrased insight from The Powder Coach's Playbook (Joey Golliver emphasizes using "real world knowledge to book learning" when teaching finishing strategies)

That quote underscores Joey's advocacy in the book for pushing beyond textbook techniques into creative, high‑margin finishes.

Types of Powder Texture Finishes You Can Use

Here is a quick guide to common texture types and when to use them:

Because powder coating is applied in precise layers and then cured, the thickness of the texture is predictable. But note: the film thickness is measured from the peaks down to the valleys of the texture, so the valleys receive less material. For that reason, applicators must ensure the low points still meet minimum protection thickness, especially for critical corrosion control tasks.

Real Texture Powder Suppliers You Can Order From

To make these finishes happen in your shop, here are real suppliers and references for textured powder coatings:

PPG Powder Coatings — Their "Texture Powder Coating" lineup includes many stock and made-to-order textured formulas (fine, coarse, wrinkled) with published gloss and durability specs. PPG Powder Coatings

Prismatic Powders — They list a "Texture" finish category on their online color shop, including options like "Black Satin Texture" and "Wrought Iron II Texture." prismaticpowders.com

Powder Buy The Pound — Offers "Fine Texture, Coarse Texture, Crinkles, Wrinkles, Veins, and Hammertone Powders." PowderBuyThePound

SpecifyQPC / Quality Powder Coating — They promote wood grain textures (e.g. Barnwood, Oak, Walnut) as special order textures. QPC - Quality Powder Coating

Tiger Coatings — Their textured powder lines include fine textures, wraps, antique veins, hammertone, and more, with technical writeups. tiger-coatings.com

When picking a supplier, request their technical data sheets (TDS) and sample chips so you can test how the texture shows on your particular substrate and lighting.

In this video Joey Golliver shows how applying and curing a wrinkle‑style powder finish over a prepped substrate leads to a dramatically different tactile result compared to a flat coat. The peaks and valleys catch light at different angles, giving depth and a "living" appearance. In the video, note how shadows accentuate the texture as the piece rotates.

That demonstration is one concrete example of how texture transforms a flat sheet into something with character, and with much more visual and functional substance than just color. Only powder coating gives you that control.

Best Practices & Tips for Working with Textured Powders

Pretreatment and cleanliness matter even more. Because valleys may trap contamination, your cleaning and degreasing steps must be impeccable.

Adjust spray settings. Use lower gun current and slower traverse speed (or heavier spray) to ensure full coverage into texture valleys.

Monitor film thickness carefully. Because of uneven surfaces, use coupons or test parts to verify you’re delivering enough coating in low spots.

Cure uniformly. Uneven heating may amplify texture contrast (or cause overcure in peaks). Use calibrated ovens and temperature monitoring.

Test final effects. Always run trial parts under your shop lighting, inspect visually and touch them to see if the texture meets expected feel.

Match performance. If using a textured clear over a color, ensure the clear has matching substrate performance (UV, corrosion, etc.).

Powder coating opens a world of texture possibilities that paint simply can't match in consistency, durability, or layering potential. From subtle sand textures to dramatic hammered and wrinkle effects, powder lets you infuse both style and function into surfaces.

Real suppliers offer off-the-shelf textured powders, and with careful process control you can deliver finishes that outperform flat paint in both looks and longevity. As Joey Golliver encourages in The Powder Coach's Playbook, using "real world knowledge to book learning" means pushing your finishing beyond the expected texture is one of those high-leverage areas.